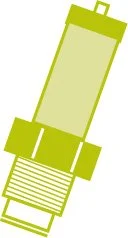

Precise Temperature control

Vinpilot® Pro

When it comes to temperature-controlled fermentation, rely on the most advanced fermentation control system in the world.

✓ 5 years warranty

✓ Control via mobile app

✓ Completely waterproof

let vinpilot® pro automate your tank

i

Level Monitoring and Control

Monitor and control tank levels by radar with VinPilot® RADAR.

The system precisely measures the current level of your tanks. In combination with VinPilot® you can also control mobile pumps automatically for accurate filling and automated blending. This saves time, reduces labor, and ensures reproducible processes.

More about Radar

i

Density Measurement

Measure sugar content and fermentation progress live.

VinPilot® BRIX continuously monitors density during fermentation. This lets you optimize fermentation temperature and automate many other processes based on the actual progress.

More about Brix

i

Controlled Nutrient Dosing

Automatic nutrient dosing as a standalone solution or fully integrated into the VinPilot® system.

VinPilot® ENODOSE controls targeted nutrient additions during fermentation, either time-based or density-based, for precise, efficient, and fully documented support of your fermentation.

More about Enodose

i

VinPilot® OXY

Precise control of push, macro- and micro-oxygenation.

Oxygen addition is software-controlled, accurately dosed, and can be combined with automatic density measurement—perfectly matched to the respective fermentation stage and process step.

More about Oxy

i

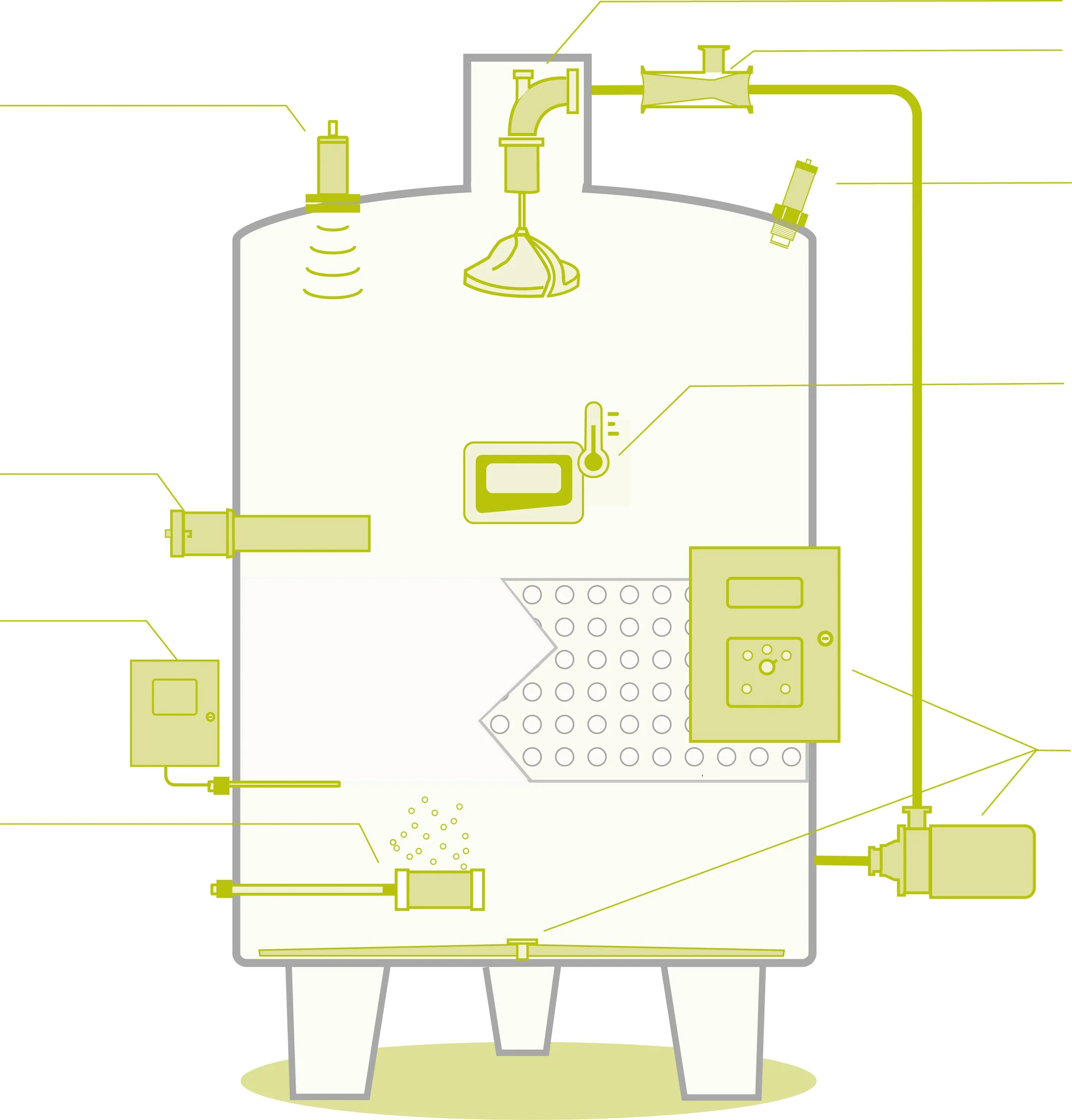

Cap Management

Wet the cap reliably from above with VinPilot® ROTOCAP.

The innovative technology ensures even and targeted wetting of the cap from above, significantly improving the extraction of color and tannins.

More about Rotocap

i

Aeration

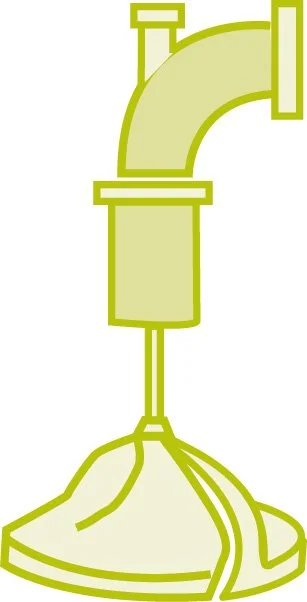

Simple, controlled aeration with VinPilot® VENTURI.

The system introduces oxygen precisely during pumping over. VinPilot® VENTURI saves working time, reduces wine loss, and can be fully integrated into the VinPilot® software for automated and repeatable aeration.

More about Venturi

i

Pressure Monitoring

Monitor and automatically regulate tank pressure with VinPilot® P-SYNC.

The system precisely measures current tank pressure and enables automatic control of pressure-dependent processes—for greater safety, efficiency, and process control.

More about P-Sync

i

Temperature Control

Accurate temperature control with VinPilot® PRO.

Cool or heat your tanks precisely and reliably. Control and monitoring are available directly at the tank, via the central VinPilot® software, or conveniently via the app—flexible and location-independent.

More about the Pro system

i

Red Wine Process Automation

Automate red wine processes intelligently with VinPilot®.

Whether pumping over, pigeage, or other red wine processes—VinPilot® controls every step automatically and reliably. Tank emptying can also be operated directly at the control cabinet for maximum control, minimal effort, and consistent results.

More about remontage

Controlled Nutrient Dosing

Automatic nutrient dosing as a standalone solution or fully integrated into the VinPilot® system.

VinPilot® ENODOSE controls targeted nutrient additions during fermentation—either time-based or density-based—for precise, efficient, and fully documented support of your fermentation.

Level Monitoring and Control

Monitor and control tank levels by radar with VinPilot® RADAR.

The system precisely measures the current level of your tanks. In combination with VinPilot® you can also control mobile pumps automatically for accurate filling and automated blending. This saves time, reduces labor, and ensures reproducible processes.

More about Radar

Density Measurement

Measure sugar content and fermentation progress live.

VinPilot® BRIX continuously monitors density during fermentation. This lets you optimize fermentation temperature and automate many other processes based on the actual progress.

More about Brix

VinPilot® OXY

Precise control of push, macro- and micro-oxygenation.

Oxygen addition is software-controlled, accurately dosed, and can be combined with automatic density measurement—perfectly matched to each fermentation stage and process step.

More about Oxy

Cap Management

Wet the cap reliably from above with VinPilot® ROTOCAP.

The innovative technology ensures even and targeted wetting of the cap from above, significantly improving the extraction of color and tannins.

More about Rotocap

Aeration

Simple, controlled aeration with VinPilot® VENTURI.

The system introduces oxygen precisely during pumping over. VinPilot® VENTURI saves working time, reduces wine loss, and can be fully integrated into the VinPilot® software for automated and repeatable aeration.

More about Venturi

Pressure Monitoring

Monitor and automatically regulate tank pressure with VinPilot® P-SYNC.

The system precisely measures current tank pressure and enables automatic control of pressure-dependent processes—for greater safety, efficiency, and process control.

More about P-Sync

Temperature Control

Accurate temperature control with VinPilot® PRO.

Cool or heat your tanks precisely and reliably. Control and monitoring are available at the tank, via the central VinPilot® software, or via the app—flexible and location-independent.

More about the Pro system

Red Wine Process Automation

Automate red wine processes intelligently with VinPilot®.

Whether pumping over, pigeage, or other red wine operations, VinPilot® controls each step automatically and reliably. Tank emptying can be operated directly at the control cabinet for maximum control, minimal effort, and consistent results.

More about remontage